Providing customers with complete wiring harness solutions and services

Information Details

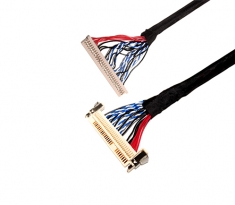

Protective measures required for abs wiring harness

Published Time:

2021-01-25 18:29

Protective measures for wiring harnesses

Wiring harness maintenance needs to consider several aspects: firstly, the selection of the harness material itself; secondly, the maintenance of the wire connections in the harness; and thirdly, the maintenance of the pin-type terminals in the harness. Haozhi will elaborate on how to better maintain the wiring harness through these aspects below.

Wiring Harness Material Selection

Wiring harnesses are generally made of multi-core soft copper wire, and there are also silver-plated wires. In many cases, a thin layer of high-conductivity silver is plated on the surface of the copper wire to improve conductivity. The most important requirement is to select the appropriate wire diameter or cross-sectional area based on the maximum current of the wire. In addition to considering the wire diameter, the environment and function of the wiring harness should also be considered. For example, the working environment of the engine is harsh, with high temperatures, and many corrosive gases and liquids. Therefore, when selecting wires, it is necessary to use wires that are heat-resistant, corrosion-resistant, abrasion-resistant, and vibration-resistant. There are many types of wires, and each country has different classifications, different points to note, and different manufacturing standards. ABS wiring harness factories need to select wires based on the specific working environment and specific requirements of the ABS wiring harness during production. Polyvinyl chloride (PVC) insulated wires are commonly used.

Maintenance of Wire Connections in the Wiring Harness

The connection points between wires in a wiring harness are called harness connection points. Connection points are commonly found in instrument harnesses, audio harnesses, engine compartment harnesses, and air conditioning harnesses. Signals can be transmitted between switches and multiple electrical appliances through these connection points, so effective measures are necessary. Generally, after the connection points are connected, the copper wires of the wire cores are exposed, easily oxidized, and multiple connection points wrapped together in the harness can easily cause cross-talk between connection points, leading to short circuits. In severe cases, this can cause a fire. Therefore, wiring harness connection points must be protected with materials that have good insulation properties.

The materials used to wrap connection points vary depending on the working environment. PVC tape is generally used for wiring harness connection points that are less affected by the environment, such as instrument harnesses, overhead harnesses, body harnesses, four-door harnesses, and indoor harnesses such as air conditioning harnesses. For connection points in the front compartment and engine harnesses, double-layer heat-shrink tubing is generally used to provide waterproof, high-temperature resistance, and wear resistance, but the cost is higher than that of tape.

Previous Page

Previous Page

1993/03/16