Providing customers with complete wiring harness solutions and services

Information Details

Focusing on Quality and Strengthening Enterprises - The Company's 2021 "Quality Month" Activities Conclude Successfully

Published Time:

2021-10-09 17:22

Editor's Note

Quality Month is a mass quality activity widely carried out internationally. Under the guidance and deployment of relevant government departments in China, it is mobilized nationwide every September in various forms, encouraging the entire society, especially enterprises, to actively participate. With the main goal of improving quality levels, it promotes social co-governance of quality and is a major quality activity and mass quality theme activity organized over the long term. This September marks the 44th National Quality Month.

Shuangfei Company has always aimed to prioritize quality and comprehensively move towards a "zero" defect quality management era. It carefully planned and organized a series of Quality Month activities.

Careful Planning & Active Quality Promotion

Through various methods, such as distributing quality knowledge booklets to site foremen and frontline employees, widespread publicity and activity guidance were conducted to create a positive atmosphere where everyone cares about, values, and pursues quality.

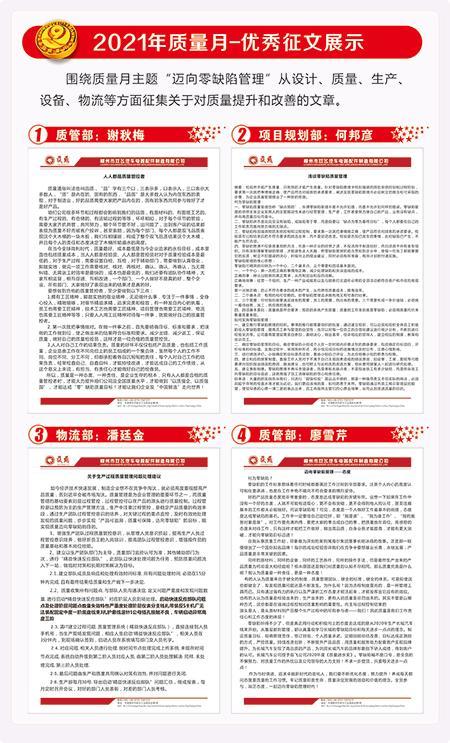

The headquarters and various subsidiaries actively carried out quality essay writing activities. During the activity, a total of 8 essays were received. After the preliminary and final reviews, 4 essays won awards: "Everyone is a Quality Controller," "A Brief Discussion on Zero-Defect Quality Management," "Suggestions on Handling Quality Management Issues in the Production Process," and "Towards Zero-Defect Management - Attitude."

Deep Management & Improvement for Efficiency Enhancement; Self-Inspection and Rectification Activities

Through self-inspections in factories 01/02/03, a total of 22 problems were identified and categorized into 3 major issues. Targeted rectification was carried out by region, gradually correcting relevant process and quality details that arose during production.

Through such process quality inspections, the quality concept is gradually shifting from "I have to inspect" to "I want to inspect," forming a good atmosphere of self-inspection. This not only enhances the inspection capabilities of frontline managers but also promotes the upward development of workshop quality culture.

Strengthening Quality Culture Construction

"A journey of a thousand miles begins with a single step." Quality incentive activities were organized to establish goals, promote advanced practices, and enhance the enterprise's sense of responsibility for quality.

On September 25th, Shuangfei Company's Quality Management Department, under the theme of "Integrity and Unity, Quality is Essential," organized a hiking activity for all department employees to Duole Park, including fun games. This activity achieved the goals of self-challenge, willpower training, and team building, effectively enhancing communication among employees, fostering a spirit of teamwork, and strengthening employee cohesion and combat effectiveness, laying a solid foundation for achieving the fourth-quarter quality goals!

Strengthening Quality Control & Consolidating Quality Foundation

On September 30, 2021, the company held a "Quality Month" summary meeting, attended by Executive Vice General Manager Chen Fengjiao, Deputy General Manager of the Manufacturing Center Ma Fuliang, Deputy General Manager of the Technology Center Qin Meiyang, host factory SQE, and representatives from various departments. At the meeting, Manager Chen comprehensively summarized the "Quality Month" activities and put forward clear requirements for future quality work. She required company employees to further improve product quality and service quality in future quality work to contribute to the high-quality and sustainable development of the enterprise.

Manager Chen's Address at the Quality Exhibition

The exhibition showcased our company's wiring harness products for various clients, including passenger car wiring harnesses, commercial vehicle wiring harnesses, engineering machinery wiring harnesses, new energy high-voltage cables, valve plate wiring harnesses, and through-cylinder wiring harnesses.

Director Li from the Technology Center, through the display of physical wiring harnesses, explained the design, quality control points, and key control equipment of different types of wiring harnesses.

Through sharing, discussion, and learning, we are moving towards "zero-defect" quality.

SGMW's Zhong affirmed the importance Shuangfei places on quality work and suggested continuing to improve quality.

Yi from Liugong Excavator provided valuable suggestions for targeted improvements.

Zhou from Liuqi Commercial Vehicle put forward requirements for benchmarking and improving our wiring harnesses and accelerating the promotion of information technology.

At the exhibition, host factory clients provided guidance and exchanged ideas on quality work, hoping that both sides would improve together in future quality control cooperation. Finally, they wished Shuangfei steady progress towards a new stage of "zero" defect quality management.

Moving Towards a "Zero" Defect Quality Management Era

Quality is the foundation of enterprise development. We will uphold quality and pursue craftsmanship, continuing to carry out quality improvement actions, using the "craftsman spirit" to focus on quality, and jointly creating an atmosphere where "everyone creates quality and everyone enjoys quality." We will further improve the quality management system, clarify quality management responsibilities, strengthen quality culture construction, enhance the company's soft power, and comprehensively move towards a "zero" defect quality management era, providing customers with better products and services.

Activity, quality, improvement, implementation, quality management, defects, everyone, employees, moving towards

Previous Page

Previous Page

1993/03/16