Providing customers with complete wiring harness solutions and services

Information Details

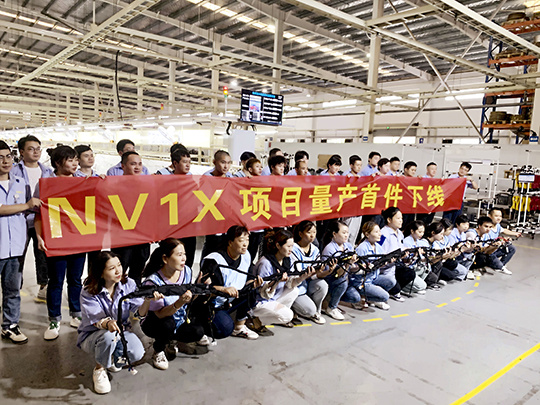

Good news in autumn - Derun's Shuangfei Company successfully launched the NV11 & 12 projects

Published Time:

2022-10-08 15:56

In September, the harvest season, Derun Shuangfei's Niuchuang NV11&12 projects were successfully launched, marking another milestone in Derun Shuangfei's wire harness manufacturing capabilities.

The Niuchuang NV11&12 projects are for a mid-to-large SUV new energy vehicle model. The vehicle has a large number of circuits, making the assembly process very challenging. The floor harness assembly, the most difficult part of the entire vehicle harness to produce, currently boasts the highest number of circuits and longest length in any Derun Shuangfei project. Parameters such as single harness weight, tooling board drawing length, harness assembly circuit, and total harness length have all reached new highs.

The structural characteristics of the floor harness assembly led to unavoidable challenges during production. In the pre-assembly process, the long length of individual slides in the single-piece flow, and the large number of circuits per part number resulted in many wires on the slide, making the slide movement time-consuming and laborious, and hindering improvements in pre-assembly efficiency. In the assembly process, due to the large number and length of circuits per part number, the difficulty of wire hanging operations increased under a single-flow production model, affecting assembly efficiency and making it impossible for conventional production to meet customer capacity demands. These difficulties presented the biggest challenges for Derun Shuangfei during the wire harness production and assembly phase.

To meet this significant challenge, Derun Shuangfei united its efforts with the support of the headquarters technical center to gradually overcome the technical difficulties. In the pre-assembly process, the conventional single-flow production model was abandoned in favor of a segmented flow production model, which reduced the time-consuming and laborious aspects of the pre-assembly process and effectively addressed the wire hanging challenges in the assembly process. In the assembly process, single-sided floor-standing assembly lines of the appropriate size were purchased, with a flow rate capable of producing 200 sets in a 10-hour shift, meeting customer capacity requirements.

The successful launch of the Niuchuang NV11&12 projects reflects the hard work of colleagues from various departments at Derun Shuangfei and the strong support from the group headquarters. For Derun Shuangfei, the success of the NV11&12 projects will add a brilliant chapter to the company's vigorous development. We will continue to provide customers with even better products and services with even greater enthusiasm!

1993/03/16